FLOWMASTER measuring and computing complex and input/output modules

The FlowMaster measuring and computing complex (hereinafter referred to as MCC) and additional input/output modules are microprocessor devices for processing signals from field devices (temperature, pressure, differential pressure sensors, chromatographs) and calculating, on their basis, flow readings and other process parameters of natural gas in real time.

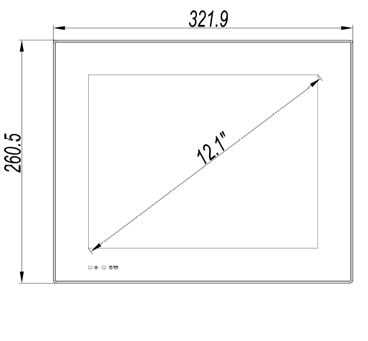

Overall and installation dimensions of the computer (front view)

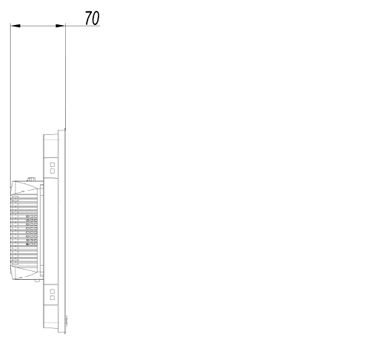

Overall and installation dimensions of the computer (side view)

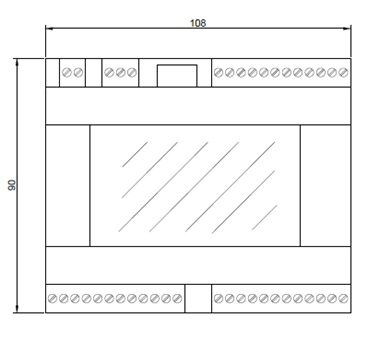

Overall and installation dimensions of the input/output module (front view)

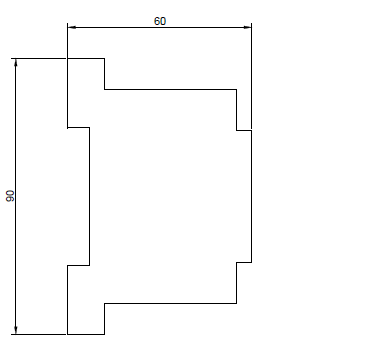

Overall and installation dimensions of the input/output module (side view)

Scope of application of ICS and I/O modules:

- Commercial natural gas metering units;

- Technological gas metering units;

- Automated dispatch control and metering systems

Delivery package includes the following:

- Flow computer

- Input/output module

Main technical characteristics of the flow computer

|

Processor |

Intel N97 |

|

Processor generation |

Alder Lake |

|

Processor clock speed |

3.6 GHz |

|

RAM type |

DDR4 |

|

RAM slots |

1xSODIMM |

|

RAM capacity |

16 Gb |

|

Max RAM |

16 Gb |

|

Video adapter type |

Integrated |

|

Drive type |

SSD |

|

Drive form factor |

M.2 |

|

Drive capacity |

256 Gb |

|

Display type |

LCD TFT |

|

Display size |

12.1 » |

|

Display resolution |

1024×768 |

|

Aspect ratio |

4:3 |

|

Brightness |

350 kd/m2 |

|

Contrast |

800~1 |

|

Touch screen |

+ |

|

Network adapter |

Intel i210-AT |

|

Number of Ethernet ports |

2 |

|

Number of 10/100/1000 Mb Ethernet |

2 |

|

Number of serial ports |

2 |

|

Number of RS-232/485 connectors |

2 |

|

Number of USB connectors |

6 |

|

Number of USB v2.0 |

2 |

|

Number of USB v3.x |

4 |

|

Number of SATA.3 connectors |

1 |

|

Number of M.2 connectors |

1 |

|

Cooling type |

Passive |

|

IP protection of the front panel |

IP65 |

|

Mounting |

Tabletop, panel mount, VESA 100×100, ARM mount |

|

Watchdog timer |

Software |

|

Power supply |

12…28 В DC |

|

Type of power supply |

External AC/DC Adapter |

|

OS support |

Windows 10, Windows 11, Astra Linux |

|

Dimensions (H*W*D), mm |

260.5 x 321.9 x 70 |

|

Operating temperature |

-20…60°C |

|

Humidity |

5-95% |

Main technical characteristics of the input/output module

| Parameter name | Value | |

| Supply voltage, V | DC 10-36 | |

| Power consumption, W | 5 | |

| Dimensions (H*W*D), mm | 90 x 108 x 60 | |

| Operating temperature range, °C | -20…+70 | |

| Ambient pressure, kPa | 84…106 | |

| Relative air humidity | 30…80 at +35°C | |

| Mounting type | On 35mm DIN rail | |

| Protection level | IP20 | |

| Communication ports | Ethernet, RS-485 | |

| Modbus TCP server | +, up to 3 active clients | |

| Modbus RTU server | + | |

| Web interface | + | |

| Display | +, 2.4″, colored | |

| Display resolution | 320 x 240 | |

| Analog inputs | Quantity | 8 |

| Measurement range, mA | 0-25 | |

| ADC resolution, bit | 24 | |

| Current measurement resolution, μA on display and in modbus registers | 1/1 | |

| Input type | Passive | |

| Input resistance, Ohm | 200 | |

| Protection | Overvoltage protection up to 40V, reverse polarity, current limitation up to 30mA | |

| Limits of permissible reduced error of current measurement in NU, % | 0,04 | |

| Limits of permissible reduced error of current measurement in the range of operating temperatures, % | 0,04 | |

| Galvanic isolation, V | 500, group combined with analog output | |

| Analog outputs | Quantity | 2 |

| Formation range, mA | 0-24 | |

| DAC bit depth, bit | 16 | |

| Current setting resolution, µA on display and in modbus registers | 1 | |

| Output type | Active | |

| Protection | From overvoltage up to 40 V, reverse polarity, current limitation up to 30 mA | |

| Limits of permissible reduced error of current measurement in NU, % | 0,1 | |

| Limits of permissible reduced error of current measurement in the range of operating temperatures, % | 0,1 | |

| Galvanic isolation, V | 500, group combined with analog inputs | |

| Discrete inputs | Quantity | 8 |

| Type according to GOST IEC 61131-2-2012 | 2 | |

| Nominal voltage, V | 24 | |

| Maximum voltage, V | 32 | |

| Discrete outputs | Quantity | 8 |

| Type according to GOST IEC 61131-2-2012 | 2 | |

| Nominal voltage, V | 24 | |

| Maximum voltage, V | 32 | |

- Built-in human-machine interface (HMI) allows monitoring current process parameters and performing system diagnostics without additional equipment;

- Possibility of connecting up to 10 input/output modules of various configurations to the computer;

- Built-in OPC UA and Modbus TCP/IP servers for transmitting data to the upper level;

- Password-protected device access menu allows protecting the program and data from unauthorized access;

- Non-volatile memory of the device allows saving current data and entered programs and resuming operation at the interruption point in the event of a power failure;

- Possibility of storing reports for an annual period;

- Flexible configuration system, support for common signal types allows using a wide range of field devices without being tied to a specific manufacturer;

- Possibility of operation in redundant mode;

- Modular design allows configuring ICS or various applications;

- Possibility of using input/output modules as separate devices due to the built-in Modbus TCP/IP server;

- Free software.