The production facility is the core of any engineering enterprise. It is where concepts are transformed into finished solutions and complex tasks receive precise engineering responses.

The production workshop located in Uralsk, with an area exceeding 1,500 m², is a high-tech environment equipped with precision modern equipment, including the BODOR A3 laser cutting machine, the T-230 pipe-threading lathe, and the fifth-generation Puma GT 2600 horizontal turning center. The facility is divided into specialized zones. This approach enables the efficient execution of tasks of varying complexity while ensuring high precision and product reliability.

WEST OIL Engineering Company performs metrological support at all stages of the production cycle and holds Category I and II licenses for construction and installation works. The production processes are certified in accordance with international ISO standards and the company holds an industrial certificate of a domestic manufacturer. This enables participation in large-scale projects and tenders.

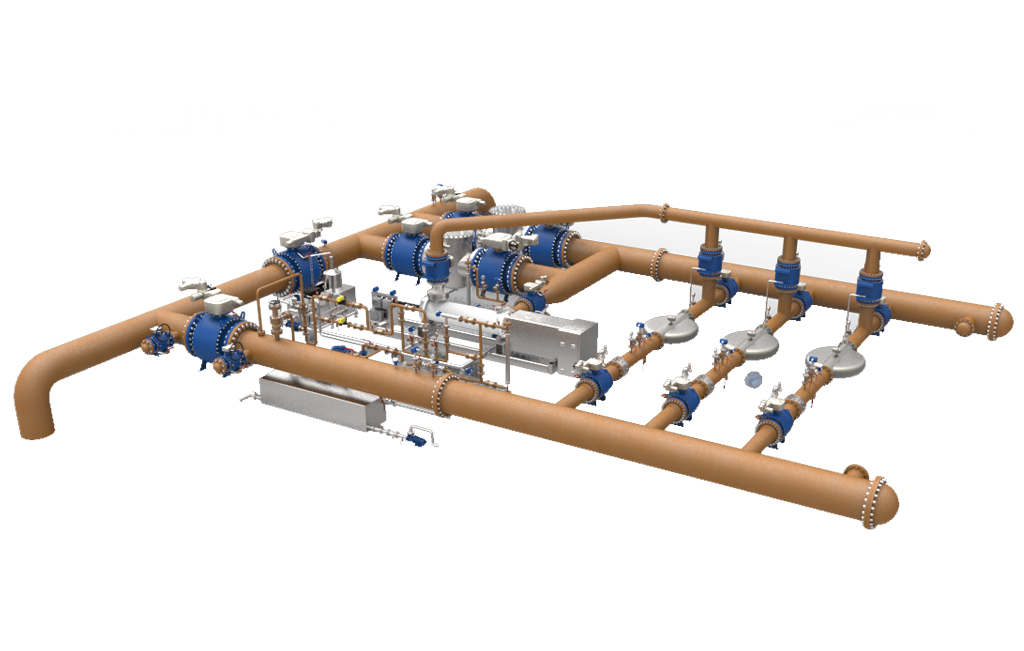

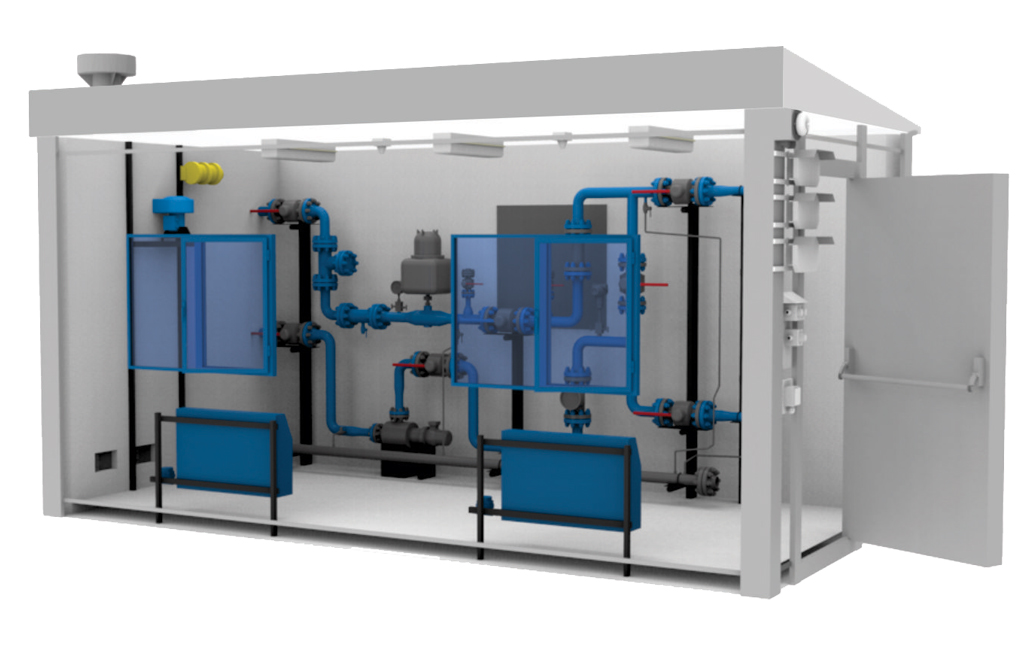

We manufacture engineering systems of various complexity and configuration for key industries:

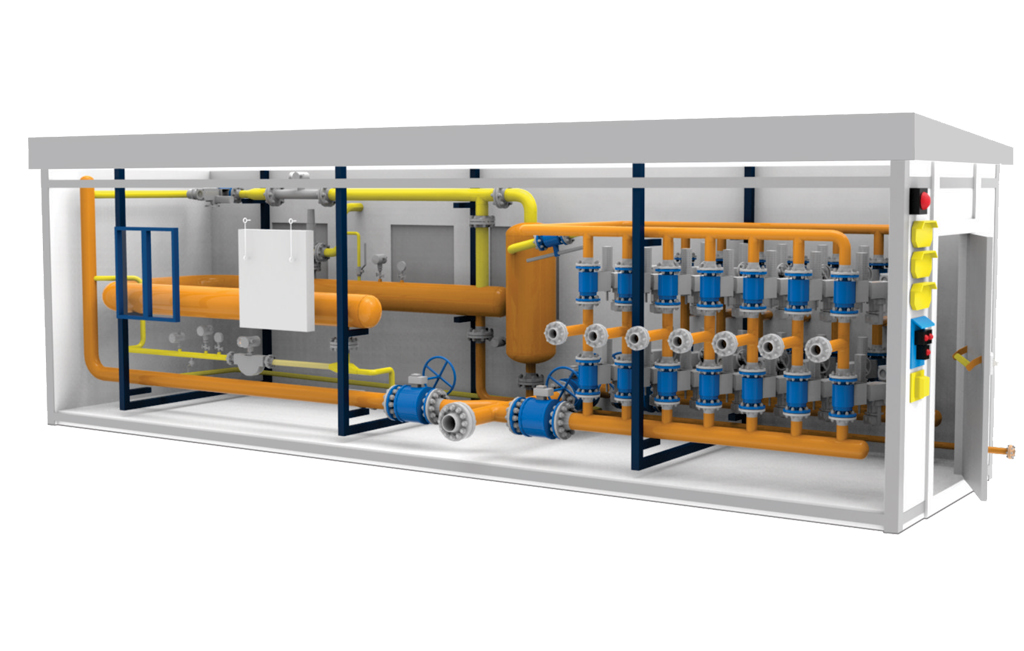

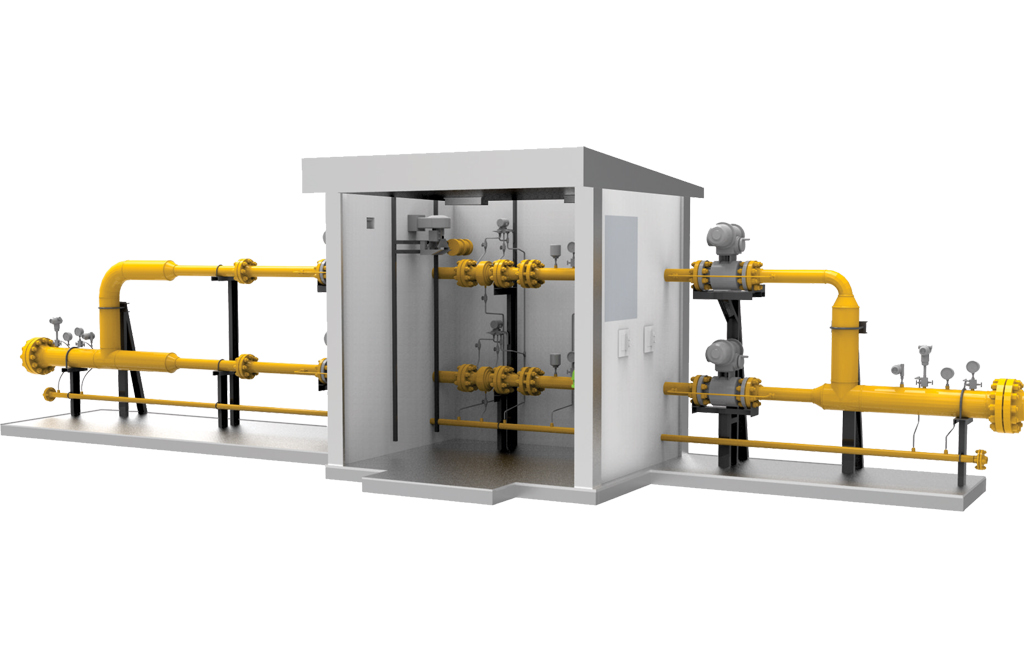

CIOM – Crude Oil Quantity and Quality Measurement System

OQMB – Oil Quality Measurement Block

AGZU – Automated Group Metering Unit

OWFRU – Oil Well Flow Rate Measurement Unit

GFMS – Gas Flow Measurement System (Commercial Gas Metering Unit)

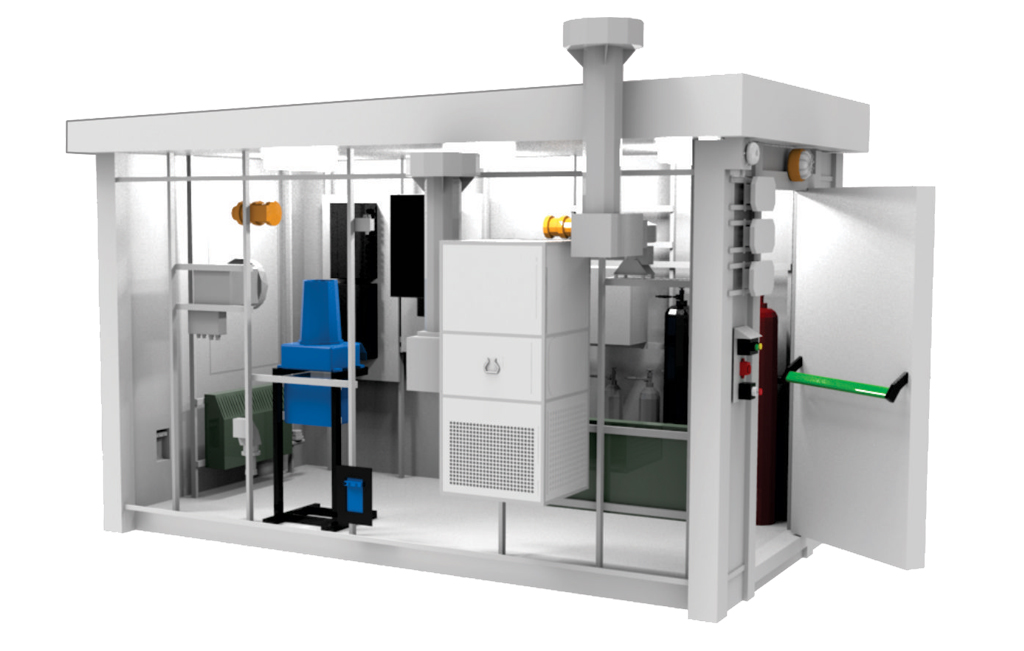

GQAB – Gas Quality Analysis Block

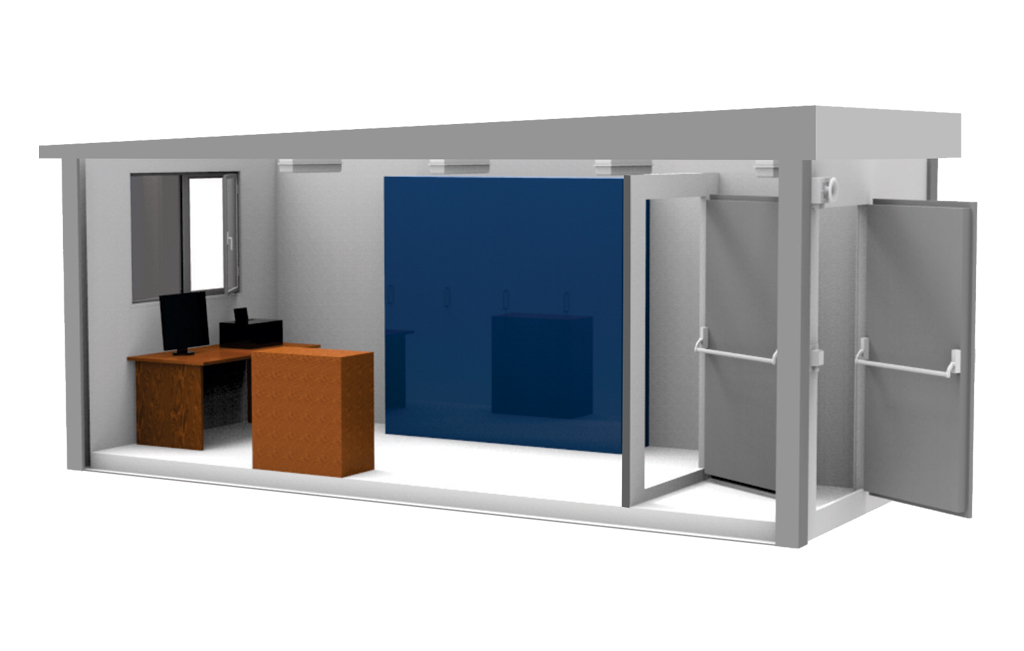

MBU – Modular Block Building

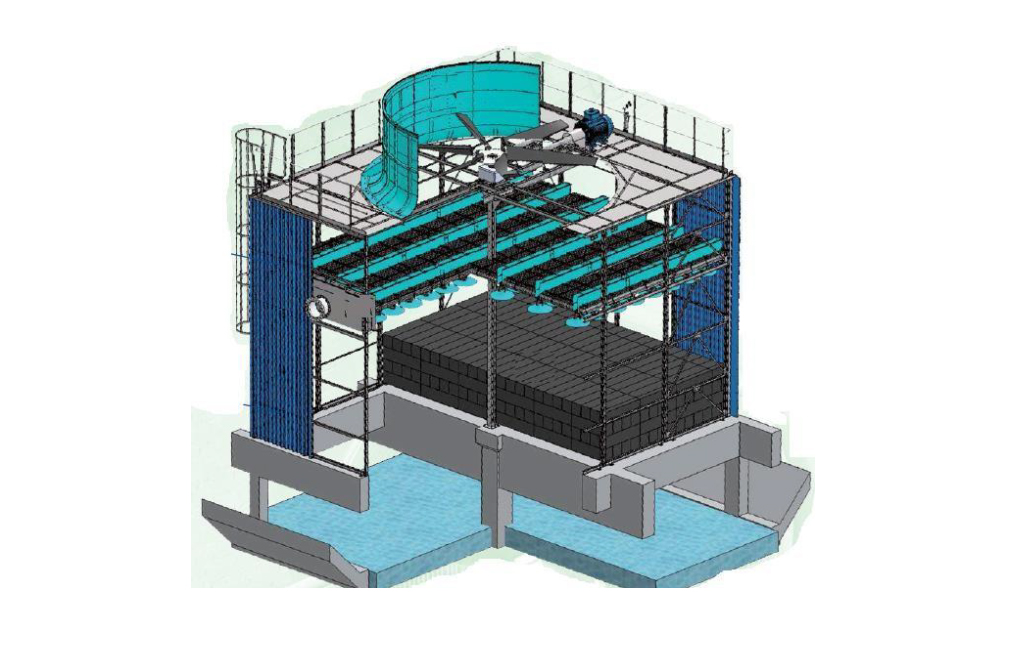

Cooling Towers – Equipment for industrial water cooling systems

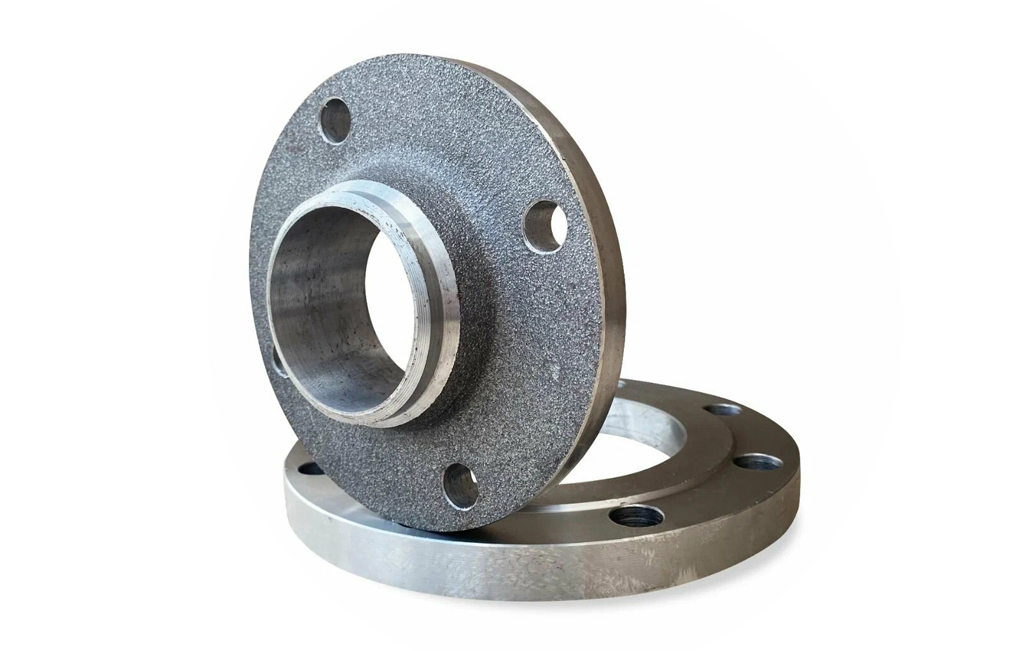

In-House Production of Components:

Chromatographs

Temperature sensors

Sampling systems

Pressure sensors

Flanges

Gate valves (shut-off valves)

Flow-restricting devices (orifice devices)

Straight pipe sections

FLOWMASTER measuring and computing complex and input/output modules

Why Choose WEST OIL

By choosing WEST OIL, you receive not only high-quality equipment, but also the assurance of its reliable operation throughout the entire service life. We deliver dependable solutions that enable our partners to effectively solve production challenges and achieve new levels of performance.

Advantages of Our Production Facility

Custom Solutions: Manufacturing of products tailored to the customer’s specific requirements.

Full Transparency: Customer oversight is possible at all stages of the production process.

High Quality: Strict quality control at every stage — from raw materials to final assembly.

Certification: Compliance with international standards and market requirements.

Reliability: Guaranteed stable operation of equipment under any operating conditions.