- Development of the Rozhkovskoye field

Development of the Rozhkovskoye field

Operational water metering unit, Commercial condensate metering unit, Commercial gas metering unit for Neftestroyservis Ltd. LLP

Location area: Kazakhstan, West Kazakhstan region, Rozhkovskoye field Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Endress+Hauser, Wika. The system provided solutions to the following customer tasks: Operational water metering with standardized accuracy; Commercial gas metering; Commercial condensate metering. Year: 2025

Implementation period: 10 months.

- System for measurement of oil quantity and quality (SMOQQ)

Year: 2025

Implementation period: 10 months.

System for measurement of oil quantity and quality (SMOQQ)

for ZHALGIZTOBEMUNAY LLP

Location area: Kazakhstan, Mangistau region Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determining of mass flow rate of oil; Determining of volumetric flow rate of oil; Determining of oil density; Determining of moisture content in oil; Conducting control of metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (PTVU); Verification of a stationary PTVU using a reference unit (RU); Registration, storage and transmission of information to the telemetry system and SCADA.

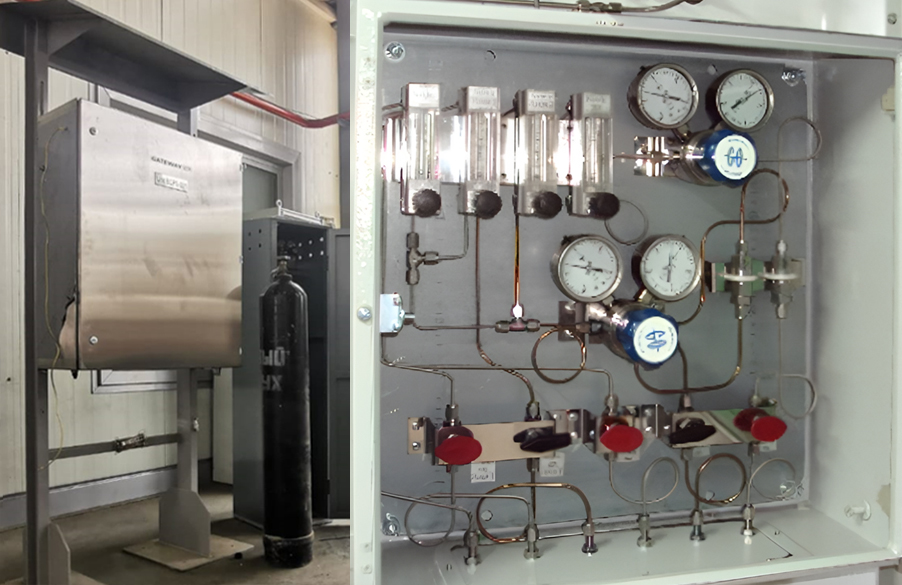

- Sampling system

Sampling system

for KPO b.v. through the request of Gateway LLP

Location area: Kazakhstan,

West Kazakhstan region, Karachaganak fieldScope of works: Development of technical solution; Equipment supply; Engineering;

Assembly and acceptance testing; Installation and commissioning; Commissioning of the system.Brands that were used: Parker, FITOK, WIKA. The operator’s room provided solutions to the following customer tasks: Safe collection of fixed volume samples under high pressure. Year: 2024

Implementation period: 2 months.

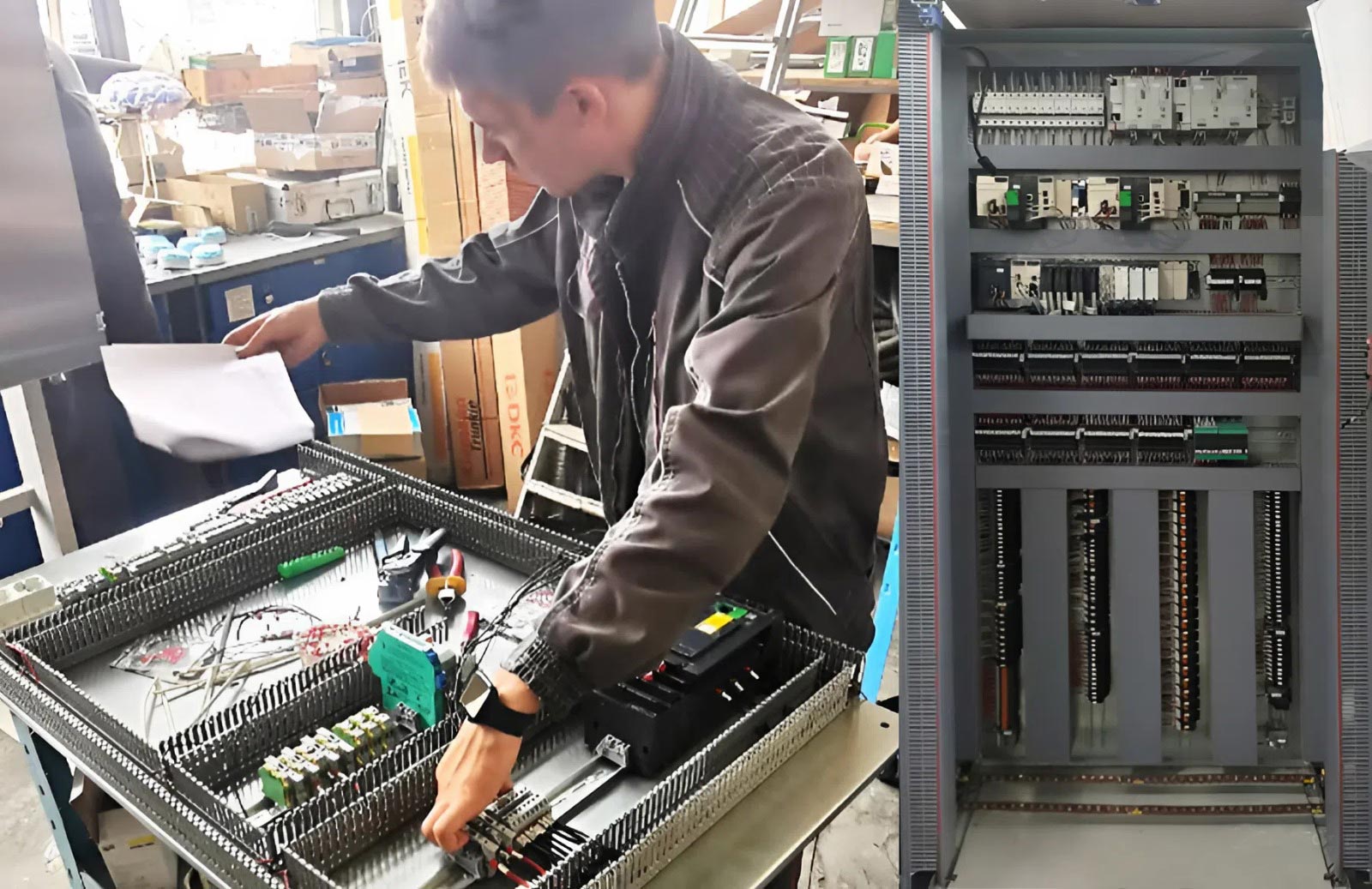

- Automated process control systems (APCS)

Year: 2024

Implementation period: 4 months.

Automated process control systems (APCS)

Automated process control systems (APCS)

Location area: Kazakhstan,

West Kazakhstan region, Karachaganak fieldScope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Visualization of data from all field devices and equipment in real time; Remote control of process equipment; Uninterrupted and automated operation of equipment.

- Modernization of measuring instruments of TPP-1, TPP-2 and TPS gas metering units (1st stage)

Modernization of measuring instruments of TPP-1, TPP-2 and TPS gas metering units (1st stage)

for Mangistau Nuclear Power Plant LLP

Location area: Kazakhstan, Mangistau region, Aktau. Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Siemens, Emerson, Построение систем SCADA The system provided solutions to the following customer tasks: Determination of volumetric flow rate of natural gas; Registration, storage and transmission of information to the telemetry system and SCADA. Year: 2024

Implementation period: 12 months.

- Automated group metering unit (AGMU)

Year: 2024

Implementation period: 8 months.

Automated group metering unit (AGMU)

15 units of AGMU direct contract with Ozenmunaigas JSC

Location area: Kazakhstan, Mangistau region,

ZhanaozenScope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and commissioning; Commissioning of the system. Brands that were used: KROHNE, Schneider Electric, Wika. The operator’s room provided solutions to the following customer tasks: Determination of mass flow rate of gas and oil emulsion; Determination of pressure, temperature, density; Conversion, storage and visualization of the listed parameters.

- Automated group metering unit (AGMU)

Automated group metering unit (AGMU)

18 units of AGMU direct contract with Embamunaigas JSC

Location area: Kazakhstan, Atyrau region, Dossormunaigas Oil and Gas Production Authority,

Zhylyoimunaigas Oil and Gas Production AuthorityScope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Installation and commissioning; System commissioning. Brands that were used: KROHNE, Schneider, Electric, Wika. The system provided solutions to the following customer tasks: Determination of mass flow rate of gas and oil emulsion; Determination of volumetric flow rate of gas and oil emulsion; Determination of pressure, temperature, density; Conversion, storage and visualization of the listed parameters. Year: 2024

Implementation period: 3 years.

- Reconstruction of the circulating water supply system in terms of replacing the cooling tower

Year: 2022

Implementation period: 14 months.

Reconstruction of the circulating water supply system in terms of replacing the cooling tower

for Uralskaya TPP of Zhaiykteploenergo JSC through the request of the Department of Housing and Public Utilities, Passenger Transport and Highways of Uralsk State Institution

Location area: Kazakhstan, Mangistau region Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determining of mass flow rate of oil; Determining of volumetric flow rate of oil; Determining of oil density; Determining of moisture content in oil; Conducting control of metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (PTVU); Verification of a stationary PTVU using a reference unit (RU); Registration, storage and transmission of information to the telemetry system and SCADA.

- Automated process control systems (APCS)

Automated process control systems (APCS)

Commercial gas metering units of Zhaikmunai LLP 3 pcs.

Location area: Kazakhstan, Mangistau region, Aktau. Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Siemens, Emerson, Построение систем SCADA The system provided solutions to the following customer tasks: Determination of volumetric flow rate of natural gas; Registration, storage and transmission of information to the telemetry system and SCADA. Year: 2021

Implementation period: 8 months.

- System for measurement of oil quantity and quality (SMOQQ)

Year: 2020

Implementation period: 1,2 years.

System for measurement of oil quantity and quality (SMOQQ)

for Munai-Tas JSC through the request of Zeinet LLP

Location area: Kazakhstan, Atyrau region, Shmanovo Oil Pumping Station Scope of works: Development of technical solutions; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determination of mass flow rate of oil; Determination of volumetric flow rate of oil; Determination of oil density; Determination of moisture content in oil; Conducting control of the metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (TPVU); Verification of a stationary TPVU using a reference instrument block (RIB); Registration, storage and transmission of information to the telemetry system and SCADA.

- Automated group metering unit (AGMU)

Automated group metering unit (AGMU)

26 units of AGMU for Ozenmunaigas JSC through the request of Munaitelecom LLP

Location area: Kazakhstan, Mangistau region, Zhanaozen Scope of works: Development of technical solutions; Detailed design; Equipment supply; Engineering; Installation and commissioning. Brands that were used: KROHNE,

Schneider Electric,

Wika.The system provided solutions to the following customer tasks: Determination of mass flow rate of gas and oil emulsion; Determination of mass flow rate of gas and oil emulsion; Determination of pressure, temperature, density; Conversion, storage and visualization of the listed parameters. Year: 2020

Implementation period: 10 months.

- Engineering, supply of materials and machinery, works on the instrumentation and process control systems, construction and commissioning of the first and second start-up complexes for the project: “Increasing the capacity of the Kazakhstan-China oil pipeline”

Year: 2020

Implementation period: 12 months.

Engineering, supply of materials and machinery, works on the instrumentation and process control systems, construction and commissioning of the first and second start-up complexes for the project: “Increasing the capacity of the Kazakhstan-China oil pipeline”

for Munai-Tas JSC through the request of GAZ Story montazh KZ LLP

Location area: Kazakhstan, Mangistau region Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determining of mass flow rate of oil; Determining of volumetric flow rate of oil; Determining of oil density; Determining of moisture content in oil; Conducting control of metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (PTVU); Verification of a stationary PTVU using a reference unit (RU); Registration, storage and transmission of information to the telemetry system and SCADA.

- Loading and unloading operations control room Integrated control rooms (ICR)

Loading and unloading operations control room Integrated control rooms (ICR)

for Topan LLP

Location area: Kazakhstan, Mangistau region, Aktau. Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Siemens, Emerson, Построение систем SCADA The system provided solutions to the following customer tasks: Determination of volumetric flow rate of natural gas; Registration, storage and transmission of information to the telemetry system and SCADA. Year: 2019

Implementation period: 2 months.

- Development of design and estimate documentation

Year: 2019

Implementation period: 6 months.

Development of design and estimate documentation

for KazGPZ LLP

Location area: Kazakhstan, Mangistau region Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determining of mass flow rate of oil; Determining of volumetric flow rate of oil; Determining of oil density; Determining of moisture content in oil; Conducting control of metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (PTVU); Verification of a stationary PTVU using a reference unit (RU); Registration, storage and transmission of information to the telemetry system and SCADA.

- System for measurement of oil quantity and quality (SMOQQ)

System for measurement of oil quantity and quality (SMOQQ)

for Embamunagas JSC through the request of Successful attempt LLP

Location area: Kazakhstan, Atyrau region, Prorva Oil Delivery Point Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. The system provided solutions to the following customer tasks: Determination of mass flow rate of oil; Determination of volumetric flow rate of oil; Determination of oil density; Determination of moisture content in oil; Conducting control of the metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (TPVU); Verification of a stationary TPVU using a reference instrument block (RIB); Registration, storage and transmission of information to the telemetry system and SCADA. Year: 2019

Implementation period: 6 months.

- Automated process control systems (APCS)

Year: 2017

Implementation period: 1 months.

Automated process control systems (APCS)

Automation of Embamunaigas GFMS. Block architecture for building a program on a gas unit, which subsequently reduced the time for designing such products.

Location area: Kazakhstan, Mangistau region Scope of works: Development of technical solution; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Emerson, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determining of mass flow rate of oil; Determining of volumetric flow rate of oil; Determining of oil density; Determining of moisture content in oil; Conducting control of metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (PTVU); Verification of a stationary PTVU using a reference unit (RU); Registration, storage and transmission of information to the telemetry system and SCADA.

- Marine platforms and sector light masts

Marine platforms and sector light masts

for Tengizchevroil LLP through the request of AVENCOM

Location area: Kazakhstan, Mangistau region, Aktau. Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Siemens, Emerson, Построение систем SCADA The system provided solutions to the following customer tasks: Determination of volumetric flow rate of natural gas; Registration, storage and transmission of information to the telemetry system and SCADA. Year: 2017

Implementation period: 6 months.

- Integrated control room (ICR)

Year: 2017

Implementation period: 6 months.

Integrated control room (ICR)

for Tengizchevroil LLP through the request of AVENCOM

Location area: Kazakhstan, Atyrau region Scope of works: Development of technical solutions;

Detailed design;

Equipment supply;

Engineering.The operator’s room provided solutions to the following customer tasks: Visualization of data from all field devices and equipment in real time;

Remote control of process box equipment (valves, pumps, ventilation and heating);

Uninterrupted and automated operation of analytical equipment in the process box;

Generating and storing reports on process technological parameters with the ability to print out.

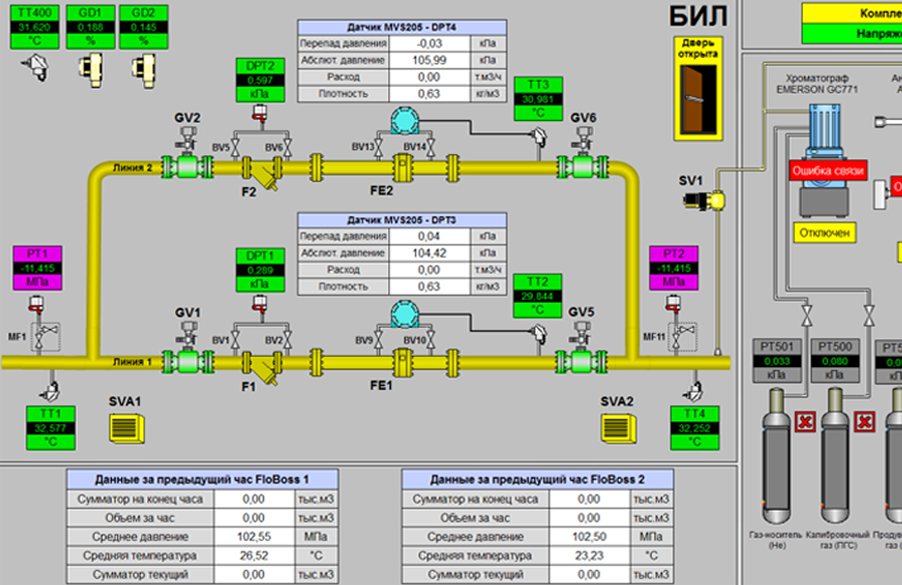

- Gas Flow Measurement System (GFMS)

Gas Flow Measurement System (GFMS)

for Embamunaigas JSC, through the request of Kerneu Limited LLP

Location area: Kazakhstan, Mangistau region, Tolkyn field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Ametek, Emerson, SGOES, Ruffneck, Building SCADA systems The system provided solutions to the following customer tasks: Automated measurement of volumetric flow rate, quantity (volume) and quality of dry purified natural gas (determination of component composition, density, dew point temperature for moisture and hydrocarbons), when conducting accounting and settlement operations. Year: 2016

Implementation period: 6 months.

- Automated process control systems (APCS)

Year: 2016

Implementation period: 6 months.

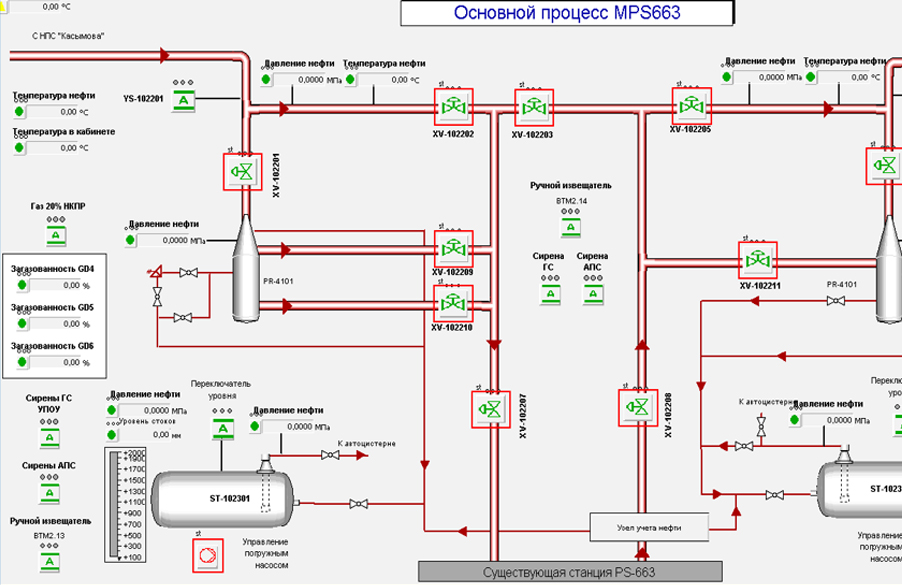

Automated process control systems (APCS)

for Zhaikmunai LLP

Location area: Kazakhstan, West Kazakhstan region, Beles Village Scope of works: Development of technical solution; Equipment supply; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Siemens, OmniFlow, iRobo, Phoenix Contact, Moxa, ABB. The operator’s room provided solutions to the following customer tasks: Visualization of data from all field devices and third-party equipment of the Oil Delivery Point in real time; Remote control of process equipment; Protection of equipment from operation in emergency modes (according to the design cause-and-effect table); Generation of reports on oil pumping volumes in accordance with the requirements of the KTO; Generation and storage of graphs of the main process parameters; Generation and storage of messages on the state of equipment and emergency situations.

- System for measurement of oil quantity and quality (SMOQQ)

System for measurement of oil quantity and quality (SMOQQ)

for KazTransOil JSC through the request of Zeinet LLP

Location area: Kazakhstan, West Kazakhstan region, Scope of works: Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning. Brands that were used: Emerson, Birdwell, SGOES, Ruffneck. The system provided solutions to the following customer tasks: Automated measurement of oil mass and determination of quality indicators during accounting operations between the delivering (Management of oil pipeline sections of the West Kazakhstan branch of KazTransOil JSC) and receiving (Transneft-Volga JSC) parties. Year: 2016

Implementation period: 10 months.

- System for measurement of oil quality (SMOQ)

Year: 2015

Implementation period: 7 months.

System for measurement of oil quality (SMOQ)

for JV Caspi Bitum LLP through the request of KIPEL LLP

Location area: Kazakhstan, industrial zone of the Atyrau bitumen plant JV Caspi Bitum LLP Scope of works: Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning. Brands that were used: Endress+Hauser,

Emerson,

Wika,

Siemens,

FMD LLC.The operator’s room provided solutions to the following customer tasks: Automated commercial accounting of oil delivered by KazTransOil JSC to the bitumen plant of JV Caspi Bitum LLP.

- System for measurement of oil quality (SMOQ)

System for measurement of oil quality (SMOQ)

for SP Tenge LLP, through the request of EKOELEKTRO LLP

Location area: Kazakhstan, Mangistau region, Tenge field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Endress+Hauser, Wika, Emerson, SGOES, Ruffneck, Building SCADA systems The system provided solutions to the following customer tasks: Automated measurement of oil mass and determination of quality indicators during accounting operations between oil supplied by JV Tenge JSC to the main pipeline system of KazTransOil JSC. Year: 2015

Implementation period: 8 months.

- Unit for measuring oil quality indicators (BMOQI)

Year: 2015

Implementation period: 5 months.

Unit for measuring oil quality indicators (BMOQI)

for Karazhanbasmunai JSC, through the request of TREI-Karaganda LLP

Location area: Kazakhstan, Mangistau region, Karazhanbas field Scope of works: Engineering;

Equipment supply;

Assembly and acceptance testing;

Installation and commissioning.Brands that were used: Endress+Hauser, Wika, Emerson, SGOES, Ruffneck. The operator’s room provided solutions to the following customer tasks: Automated determination of quality indicators during accounting transactions between the submitting (Karazhanbasmunai JSC) and receiving (Mangistau Oil Pipeline Administration of the West Kazakhstan Branch of KazTransOil JSC) parties.

- Unit for measuring the flow rate of oil wells (UMFW)

Unit for measuring the flow rate of oil wells (UMFW)

for Phystech Firma LLP

Location area: Kazakhstan, Kyzylorda region, Kumkol deposit Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Endress+Hauser,Parker,Wika. The system provided solutions to the following customer tasks: Determination of mass flow rate of gas and oil emulsion;

Determination of volumetric flow rate of gas and oil emulsion;

Determination of pressure, temperature, density; Conversion, storage and visualization of the listed parameters; The unit is mobile (based on a trailer).Year: 2014

Implementation period: 5 months.

- Gas Flow Measurement System (GFMS)

Year: 2014

Implementation period: 12 months.

Gas Flow Measurement System (GFMS)

for Ken-Sary LLP

Location area: Kazakhstan, Mangistau region, Arystanovskoye field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Metrological certification; System commissioning. Brands that were used: GE Sensing, Emerson, Ametek, Rotork, Building SCADA systems The operator’s room provided solutions to the following customer tasks: Determination of volumetric flow rate of natural gas; Control of hydrogen sulfide analysis; Determination of dew point for hydrocarbons; Determination of humidity level of natural gas; Determination of component composition of gas; Registration, storage and transmission of information to the telemetry system and SCADA.

- Unit for measuring oil quality indicators (BMOQI)

Unit for measuring oil quality indicators (BMOQI)

for JV KazGerMunai LLP

Location area: Kazakhstan, Kyzylorda region, Akshabulak field Scope of works: Engineering;

Equipment supply;

Assembly and acceptance testing.Brands that were used: Endress+Hauser, Standard, Parker, Wika, Solatron, HMD, Yokogawa The system provided solutions to the following customer tasks: Determination of oil density;

Determination of moisture content in oilYear: 2013

Implementation period: 6 months.

- Operational oil metering unit (OOMU)

Year: 2013

Implementation period: 7 months.

Operational oil metering unit (OOMU)

for Embamunaigas JSC

Location area: Kazakhstan,

Atyrau region, Centralnyi Zhanatalap field,

Zhaikmunaigas Oil and Gas Production AuthorityScope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Endress+Hauser, GE Wersamax, Wika, МВн-1.1, Yokogawa, Parker, Solatron, FlowX/S, Building SCADA systems–Cimplicity The operator’s room provided solutions to the following customer tasks: Determination of mass flow rate of oil; Determination of volumetric flow rate of oil; Determination of oil density; Determination of moisture content in oil; Registration, storage and transmission of information to the telemetry system and SCADA.

- Unit for analysis of gas quality (UAGQ)

Unit for analysis of gas quality (UAGQ)

for Ken-Sary LLP

Location area: Kazakhstan, Mangistau region, Arystanovskoye field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Ametek, Emerson, Birdwell, SGOES, Ruffneck, Building SCADA systems The system provided solutions to the following customer tasks: Determination of component composition; Determination of dew point temperature for water; Determination of dew point temperature for hydrocarbons; Determination of low concentrations of hydrogen sulfide in gas; Determination of physicochemical parameters. Year: 2013

Implementation period: 12 months.

- Unit for measuring oil quality indicators (BMOQI)

Year: 2013

Implementation period: 6 months.

Unit for measuring oil quality indicators (BMOQI)

for KMK Munai JSC through the request of IK Stroy-Tekhno LLP

Location area: Kazakhstan, Aktobe region, Kokzhide field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing. Brands that were used: Endress+Hauser, Standard, Parker, Wika, Solatron. The operator’s room provided solutions to the following customer tasks: Determination of oil density; Determination of moisture content in oil.

- Unit for measuring oil quality indicators (BMOQI) and Filtering system (FS)

Unit for measuring oil quality indicators (BMOQI) and Filtering system (FS)

for the Western Branch of KazTransOil JSC through the request of Zeinet LLP

Location area: Kazakhstan, Atyrau region, Martyshi Oil Pumping Station Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing. Brands that were used: Endress+Hauser, Standard, Parker, Wika,

Solatron, Verder Ltd., PlentyThe system provided solutions to the following customer tasks: Determination of oil density; Determination of moisture content in oil

Determination of volume flow through the BMOQI;

BMOQI filtration.Year: 2013

Implementation period: 6 months.

- Integrated control room (ICR)

Year: 2013

Implementation period: 12 months.

Integrated control room (ICR)

for Ken-Sary LLP

Location area: Kazakhstan, Mangistau region, Arystanovskoye field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Phoenix Contact, Schneider Electric, Siemens, Rittal, Emerson, Welan, Pepperl+Fush, Building SCADA systems The operator’s room provided solutions to the following customer tasks: Visualization of data from all field devices and equipment in real time;

Remote control of process box equipment (valves, pumps, ventilation and heating);

Uninterrupted and automated operation of analytical equipment in process boxes; Generating and storing reports on process technological parameters with the ability to print out.

- Integrated control room (ICR)

Integrated control room (ICR)

for Embamunaigas JSC

Location area: Kazakhstan, Atyrau region, Centralnyi Zhanatalap field, Zhaikmunaigas Oil and Gas Production Authority Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Phoenix Contact, Schneider Electric, General Electric, IEK, Spirit, Welan, Rittal, Motorola, Building SCADA systems The system provided solutions to the following customer tasks: Visualization of data from all field devices and equipment in real time; Remote control of process box equipment (pumps, ventilation and heating); Uninterrupted and automated operation of analytical equipment in the process box; Generation and storage of reports on technological process parameters with the ability to print out; Data transmission over a distance using a radio channel. Year: 2013

Implementation period: 7 months.

- Integrated control room (ICR)

Year: 2013

Implementation period: 6 months.

Integrated control room (ICR)

for JV Kazgermunai LLP

Location area: Kazakhstan, Atyrau region, Centralnyi Zhanatalap field, Zhaikmunaigas Oil and Gas Production Authority Scope of works: Detailed design; Equipment supply; Engineering; Assembly and performance testing; Installation. Brands that were used: Phoenix Contact, Schneider Electric, General Electric, IEK,

Welan, Rittal, Building SCADA systemsThe operator’s room provided solutions to the following customer tasks: Visualization of data from all field devices and equipment in real time;

Remote control of process box equipment (valves, pumps, ventilation and heating);

Uninterrupted and automated operation of analytical equipment in the process box; Generating and storing reports on process technological parameters with the ability to print out.

- Gas Flow Measurement System (GFMS)

Gas Flow Measurement System (GFMS)

for Meerbusсh LLP

Location area: Kazakhstan, Mangistau region, Kulzhan field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Ametek, GE Sensing, Emerson, Rotork, Building SCADA systems The system provided solutions to the following customer tasks: Determination of volumetric flow rate of natural gas; Control of hydrogen sulfide analysis; Determination of dew point for hydrocarbons; Determination of humidity level of natural gas; Determination of component composition of gas; Registration, storage and transmission of information to the telemetry system and SCADA. Year: 2013

Implementation period: 12 months.

- System for measurement of oil quantity and quality (SMOQQ)

Year: 2012

Implementation period: 12 months.

System for measurement of oil quantity and quality (SMOQQ)

for Ken-Sary LLP

Location area: Kazakhstan, Mangistau region, Arystanovskoye field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Endress+Hauser, Parker, Wika. The operator’s room provided solutions to the following customer tasks: Determination of mass flow rate of oil; Determination of volumetric flow rate of oil; Determination of oil density; Determination of moisture content in oil; Conducting control of the metrological characteristics of Coriolis flowmeters using a stationary piston-tube verification unit (TPVU); Verification of a stationary TPVU using a reference instrument block (RIB); Registration, storage and transmission of information to the telemetry system and SCADA.

- Unit for measuring oil quality indicators (BMOQI)

Unit for measuring oil quality indicators (BMOQI)

for JV Kuatamlonmunai LLP, through the request of IC Munaigas LLP

Location area: Kazakhstan, Kyzylorda region, Kumkol field Scope of works: Equipment supply;

Engineering;

Assembly and acceptance testing.Brands that were used: Endress+Hauser, Standard, Parker, Wika, Solatron, HMD, Yokogawa. The system provided solutions to the following customer tasks: Determination of oil density;

Determination of moisture content in oil.Year: 2012

Implementation period: 6 months.

- Environmental Monitoring Station (EMS)

Year: 2012

Implementation period: 12 months.

Environmental Monitoring Station (EMS)

for KPO b.v.

Location area: Kazakhstan, West Kazakhstan region, Karachaganak field Scope of works: Equipment supply; Entry into the Register of Measuring Instruments of Kazakhstan and obtaining certificates; Installation and commissioning; Commissioning of the system. Brands that were used: Teledyne API, Met One,

OPSIS, Riello, Clark Mast.The operator’s room provided solutions to the following customer tasks: Continuous determination of the content of the main pollutants in the air – hydrogen sulfide (H2S), sulfur dioxide (SO2), nitrogen oxides (NO, NO2, NOX) and carbon monoxide (CO); Notification of customer personnel when the MAC level of the measured gases is exceeded; Determination of meteorological parameters.

- Integrated control room (ICR)

Integrated control room (ICR)

for Ken-Sary LLP

Location area: Kazakhstan, Mangistau region, Arystanovskoye field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Phoenix Contact, Schneider Electric, Siemens, Emerson, Welan, Rittal, Pepperl+Fush, Building SCADA systems The system provided solutions to the following customer tasks: Visualization of data from all field devices and equipment in real time;

Remote control of process box equipment (valves, pumps, ventilation and heating);

Uninterrupted and automated operation of analytical equipment in the process box; Generating and storing reports on process technological parameters with the ability to print out.Year: 2012

Implementation period: 12 months.

- Unit for analysis of gas quality (UAGQ)

Year: 2011

Implementation period: 12 months.

Unit for analysis of gas quality (UAGQ)

for JV Kazgermunai LLP

Location area: Kazakhstan, Kyzylorda region, Akshabulak field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: Ametek, Birdwell, Ruffneck, Stahl, SGOES The operator’s room provided solutions to the following customer tasks: Determination of dew point temperature for water;

Determination of dew point temperature for hydrocarbons.

- Units for analysis of gas quality (UAGQ)

Units for analysis of gas quality (UAGQ)

for KPO b.v.

Location area: Kazakhstan, West Kazakhstan region, Karachaganak field Scope of works: Development of technical solution; Detailed design; Equipment supply; Engineering; Assembly and acceptance testing; Installation and commissioning; Commissioning of the system. Brands that were used: DANI Instruments Spa, Ametek, Birdwell, Dräger, Ruffneck, Siemens, Building SCADA systems The system provided solutions to the following customer tasks: Determination of the component composition of gas with a high content of hydrogen sulfide (5-7%); Control over the technological process (control of the content of C5+ components); Determination of gas humidity; Determination of physical and chemical parameters. Year: 2007

Implementation period: 12 months.